UP TO THE MINUTE

Understanding the complexities of low-slope metal roofs

By McElroy Metal.

Learn the benefits of using metal on low-slope roofs and the factors to consider when choosing the right panel for your project.

Low-slope roofs are a staple in modern construction, though they often go unnoticed. By offering a blend of cost-efficiency and practical design, there’s no question why manufacturing and industrial facilities, in addition to schools and universities choose low-slope systems. Yet, beneath their seemingly straightforward appearance lies a complex interplay of materials, durability considerations and maintenance challenges that demand careful attention. Many contractors are turning to metal roofing for these applications, whether they’re replacing an existing roof or installing a new one, due to metal’s durability and lifespan. Understanding the intricacies of low-slope metal roofs can be the key to unlocking their full potential. Explore the critical aspects that could help make your next roofing project a success with us here at McElroy Metal.

Understanding low-slope roofs

Overview

While the definition of a low-sloped roof is a bit subjective, most people refer to roofs with slopes of 2:12 or below as low-sloped. New construction low-sloped roof projects often use single-ply membranes such as TPO or EPDM for a final roofing product due to the low price point but often turn to metal when it’s time to replace the original product, typically around fifteen to twenty years.

Benefits and challenges of low-sloped roofs

Like everything else, low-sloped roofs offer pros and cons. Starting with the benefits, low-sloped roofs tend to be cheaper to build. They also offer safer and easier roof access for rooftop equipment and maintenance than their steep-sloped counterparts. On the downside, low-sloped roofs can be prone to drainage issues and ponding water. As a result, they tend to require more maintenance. They also tend to accumulate snow and other debris, which, if not addressed, can lead to structural issues.

Advantages of metal roofing for low-sloped applications

Metal roofing tells a great story compared to other product options for low-sloped roofing applications.

- Life expectancy: Membrane products like EPDM and TPO offer a relatively short life expectancy of 15-20 years, while metal boasts a 50-60-year life expectancy.

- 100% recyclability: Given today's climate change concerns, the 100% material recyclability of metal roofing at the end of service life is a game changer.

- Solar host capabilities: As we continue to move toward renewable energy sources, thanks to its long life expectancy and ease of attachment, metal also shines as one of the best host sources for solar applications.

- Durability: From hurricane-force winds to hail, heavy rains, and forest fires, metal roofing stands up to Mother Nature better than other popular roofing material options.

- Energy efficiency: Today's reflective paint coating reflects much of the sun’s heat back into the atmosphere instead of pulling it into the building. Consequently, building owners can often reduce their energy costs with metal roofing over other options.

- Maintenance expectations: Other popular commercial roofing materials require annual inspections and ongoing maintenance. Metal roofing is well-known as a low-maintenance product.

- Lightweight: Metal roofing requires less building infrastructure than other roofing materials. While this is a non-issue in existing buildings, new construction projects experience cost savings in everything from footings to the type and amount of structural material required.

Types of metal roofing panels for low-slope roofs

While profile options are limitless, the most viable product families for low-sloped metal roofing products include standing seam and exposed fastened products.

Standing seam products tend to be your best bet for slopes below 1:12 and exposed fastened profiles start at slopes of 1:12; however. 2:12 & 3:12 slopes represent more common applications for exposed fastened panels.

Standing seam panels

Symmetrical versus non-symmetrical

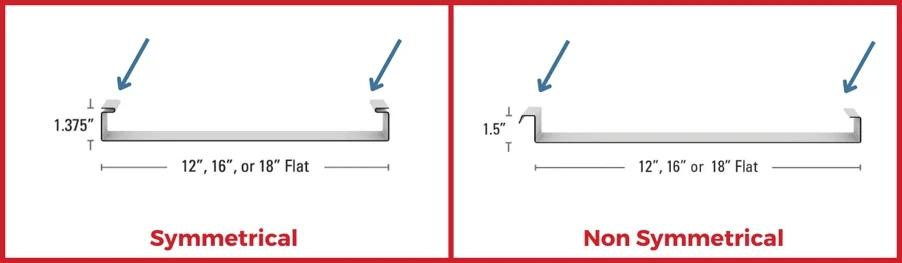

Within the major category of standing seam products, you’ll find several subcategories or smaller product families. The first defining criteria are panel shape and engagement. Standing seam panels fall into two basic styles: symmetrical and non-symmetrical. As the name implies, symmetrical panels look the same on both sides of the panel. In contrast, non-symmetrical panels look different on both sides, as the image below shows.

Symmetrical panels, (like our 238T), cost a bit more but offer individual panel replaceability. In contrast non-symmetrical panels, (like our Maxima), can be very difficult to repair without tearing off good panels to reach the necessary repair or building modification area; however, they tend to be less expensive.

Machine seamed versus snap installation

Standing seam products for low-sloped applications often require the use of a motorized seaming machine to complete the installation process. The seaming process requires extra labor and typically equipment rental, so using panels that engage together with simply a snap connection instead of seaming can present cost and labor savings. With that said, Mechanical systems routinely outperform snap seam systems in terms of structural and weathertightness performance.

Vertical leg versus trapezoidal

The horizontal and vertical legs come together at a right angle or approximately 90 degrees for vertical leg-style panel profiles. As the name implies, trapezoidal panels form a trapezoidal shape when joined together. The two styles offer vastly different aesthetics, but the differences go deeper. Vertical leg panels tend to be more expensive while offering superior weather resistance and an improved aesthetic appeal.

In contrast, trapezoidal panels can be much more difficult to make weathertight due to the large opening where the panels connect to each other. The gap on trapezoidal panels is closed off with the installation of a metal closure and tape sealant; however, it can be a challenging condition to address. Consequently, most manufacturers do not allow the use of trapezoidal panels in projects with valley conditions. The biggest benefit of trapezoidal panels is that they often represent the lowest price point for standing seam products.

Exposed fastened panels

Exposed fastened panels require the use of fasteners to penetrate the steel panel and the substrate below during the installation process. While exposed fastened systems cost less than their standing seam counterparts, it’s important to realize that every screw penetration represents the opportunity for a leak. In some cases, leaks can occur on day one due to improper fastener installation but in other cases, issues may not present themselves for 10-20 years until the washer around the fastener starts to degrade.

Replacing worn-out screws with oversized fasteners is a relatively easy and inexpensive process; however, for building owners with a distaste for ongoing maintenance, they’re probably not the best panel option. When considering exposed fastened systems for low-sloped applications, it’s critical to consult with panel manufacturers to ensure the product you select will work with your roof pitch.

Bottom line, always follow manufacturers' recommendations and understand that it’s critical to properly install fasteners (straight insertion with a properly seated washer) due to the low slope and consequently slower drainage of water/snow than steep-sloped applications.

Factors to consider when choosing the best panel

You have quite a bit to consider when selecting the best panel to use in low-sloped metal roofing applications. Below, we’ll walk you through a few of the main things to consider.

1 - Roof pitch: Roof pitch is one of your first considerations because the shape and height of the panel directly affect its ability to remain watertight at various slopes. For slopes below 1:12, you will most likely be looking at a standing seam panel where exposed fastened systems almost always require slopes above 1:12.

While you can typically use a panel at a steeper slope, you should never try to use a panel for a slope lower than recommended by the manufacturer. It’s also noteworthy that exposed fastened systems may require the addition of tape sealant at each panel lap at slopes below 3:12 to properly function.

2 - Panel length: You may be surprised by the inclusion (and priority) of panel length on this list; however, it should be one of your main considerations because using a single-piece panel is the best path forward for long-term success. Most manufacturers who specialize in low-sloped metal roofing, routinely produce panels around 60’ long. A few select manufacturers offer panels up to 80’ long with the help of stretch trailers and large manufacturing facilities. But beyond that, panel runs over 80’ often require the addition of end lap joints to connect two panels together.

It’s incredibly time-consuming to install end lap joints. When properly installed, lap joints rely on sealant tape and fasteners to keep Mother Nature at bay. Consequently, they also represent the single biggest source of leaks. Needless to say, you want to avoid panel laps whenever possible. If your panel length forces a lap situation, consider selecting a panel that can be manufactured in a single piece at the job site location. Manufacturers, like McElroy Metal, can often produce panels up to 400’ long onsite.

3 - Pan width: Wider panels tend to cost less to purchase and install more quickly than narrower panels, so they tend to be a popular choice for low-sloped applications. However, many manufacturers cap their standing seam offering at 18” wide panels. If you’re interested in reducing the cost of your project, make a 24” cover width one of your primary requirements.

Substructure: It’s also important to know the composition of the roof structure when selecting your product. Metal panel systems are designed around a specific substructure-typically referred to as open framing or solid deck. Panels designed for installation over open framing can often flex and be successfully installed over solid decks; however, the opposite is not true. If a system was designed and tested to be installed over solid deck, it typically cannot be installed over open framing.

4 - Panel gauge: Gauge refers to the thickness of the metal panel. The gauge of the material affects its deflection and ability to withstand various loads so it’s an important criterion in your consideration. Panels for low-sloped applications can range from 29 gauge on the low end for exposed fastened panels to 22 gauge on the higher end for standing seam panels.

5 - Testing requirements: Low-sloped applications tend to be most common in the commercial/industrial space. Consequently, they often require extensive uplift, air & water, impact & fire testing. Manufacturers perform various tests on their different panel styles depending on the demand for the testing and the product's ability to pass certain standards. If you need specific testing to meet your project requirements, it’s important to include that early in your decision-making process.

6 - Warranty requirements: Low slope projects often require a special type of warranty called a Weathertightness Warranty (WTW). Based on the panel style and project specifics such as roof slope and plan, some manufacturers offer WTW in periods from 5 to 20 years. These warranties are an insurance policy that the roof will not leak during the warranty period and if it does, the manufacturer is liable up to the specified amount.

Fees for these types of warranties vary based on the term length and coverage amount. If a WTW is required, it’s critical to know that before finalizing panel selection, as these types of warranties may not be available across a manufacturer’s entire product line. Finish and substrate warranties should be commonly available at no additional charge, but of course, it’s always good to confirm.

7 - Climate and weather conditions: When faced with climate extremes, it’s important to factor climate and weather conditions into your product selections. For example, standing seam panels can often offer greater uplift for high-wind areas than exposed fastened panels.

8 - Maintenance requirements: Building owners have varying appetites for ongoing maintenance. Consequently, maintenance requirements should also be factored into your decision. While exposed fastened panels represent a less expensive option, they tend to require more maintenance to check and replace fasteners over the life of the roof. Conversely, standing seam systems require minimal maintenance.

9 - Cost: Cost is always a consideration in buying decisions. When faced with a low-sloped metal roofing project, you have three main ways to control cost: panel width, panel style, and panel finish. As mentioned earlier, selecting a 24” panel width over an 18” width offers cost savings.

Regarding panel style, standing seam products cost more to purchase and install than exposed fastened panels; however, they have long been revered as the premium option for durability, minimal maintenance, and life expectancy.

Consequently, many building owners opt for a standing seam product but save money by selecting a bare product (instead of a painted finish) since low-sloped roofs aren’t often visible from the street. When a GalvalumeⓇ AZ55 coated product is selected, building owners can purchase a less expensive product without sacrificing quality and often still expect a 50-year warranty.

Installation considerations

Symmetrical versus non-symmetrical panel styles

Symmetrical systems, (like our 238T), offer the ability to start and stop at multiple points on the roof during installation. In contrast non-symmetrical panels, (like our Maxima), require the installer to use either a left-to-right or right-to-left install process which can be problematic if the entire roof isn’t ready at the same time or if the installer is waiting for curbs or other equipment to be installed.

The ability to start and stop anywhere on the roof also allows the roofing contractor to maximize his team’s efficiency by using their highly skilled workforce in challenging conditions such as valleys, while less experienced team members focus on straight panel runs. The same is simply not possible with non-symmetrical style systems.

Symmetrical panels also install more easily because the two panels simply push together whereas non-symmetrical panels need to have the hook on the leg engaged before rolling them into place. Inexperienced crews can struggle to engage the hook leg on non-symmetrical panels, and installations over open framing can be especially challenging.

The seaming machine used on the two systems also offers noteworthy differences affecting installation. The seaming machine for non-symmetrical systems often folds four thicknesses of metal during the seaming process. As a result, these seaming machines run more slowly, often run only one direction and can experience issues with much more frequency than the seaming machines typical to symmetrical systems. Symmetrical seamers typically fold only one thickness to complete the installation, so they experience far fewer issues, can often be bi-directional (meaning they can run both up and down slope), and operate at faster speeds than non-symmetrical seamers.

Longevity and repair

Symmetrical-style standing seam panels allow for single-panel repair in the field of the roof. In contrast, non-symmetrical panels can often require tear-off and removal of perfectly good panels to reach the area where a roof modification or repair is needed.

Symmetrical panels tend to be favored for commercial/industrial applications due to frequent building modifications which often require the addition of curbs to support rooftop equipment over the building life.

Original article source: McElroy Metal

Learn more about McElroy Metal in their Coffee Shop Directory or visit www.mcelroymetal.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In