UP TO THE MINUTE

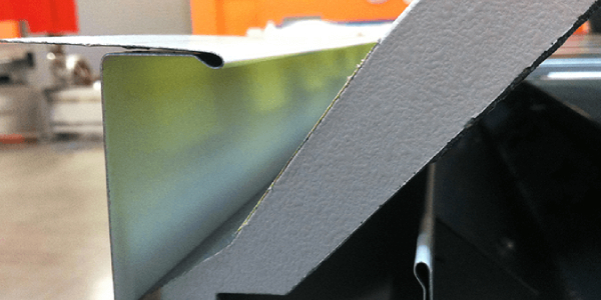

The power of a profile manipulator

By Emma Peterson.

Improve safety and efficiency with the right tool, and the training to back it up.

In this MetalTalk™, Karen Edwards spoke to Chad Rowe, Ken McLauchlan and Stephen Gosk from MetalForming about 2024 fabrication technology. One of the major pieces of machinery they discussed was profile or parts manipulators. Ken explained briefly what this machine does, “It is a way to move material through a sheet metal shop, usually through another break form or form of processing.” By automating parts of this process this tool doesn’t eliminate labor but makes it more efficient. In light of the labor shortage, this tool enables skilled technicians to do more. In addition to labor savings, a profile manipulator creates a safer work environment.

The machine they wanted to highlight specifically was the Jorns Bending Machine. Jorns is a leading name in the metal bending industry and has always been at the forefront of adopting new technology into their tools. Chad explained what makes them stand out in 2024, “The combination of their double bending and their parts manipulator, the system can be fully automated.” The Jorns machine is also very flexible, making it a great option for customers. Chad elaborated, “There's no one right answer for all of the different requests that customers come up with. One customer may want to use this piece in manner A, somebody else may want to use it in a different manner. “

The Jorns machine is a huge development in the efficiency of the metal bending industry, but even the best tools cannot operate fully without the user having the right training and knowledge to optimize it. To bridge this gap and make sure their customers are getting the best machine and experience, MetalForming places emphasis on their demo/show room. Stephen explained, “We can have customers come in and actually see their part run, train them on their machine, show them exactly what's going to be required once the machine gets them as far as supporting it.”

Read the transcript, Listen to the recording or Watch the webinar to learn about the other big developments in metal bending technology that have come out in 2024.

Learn more about MetalForming LLC in their Coffee Shop Directory or visit www.metalforming-usa.com.

About Emma

Emma Peterson is a writer at The Coffee Shops and AskARoofer™. Raised in the dreary and fantastical Pacific Northwest, she graduated in 2024 from Pacific University in Oregon with a degree in creative writing and minors in graphic design and Chinese language. Between overthinking everything a little bit, including this bio, she enjoys watching movies with friends, attending concerts and trying to cook new recipes.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In