UP TO THE MINUTE

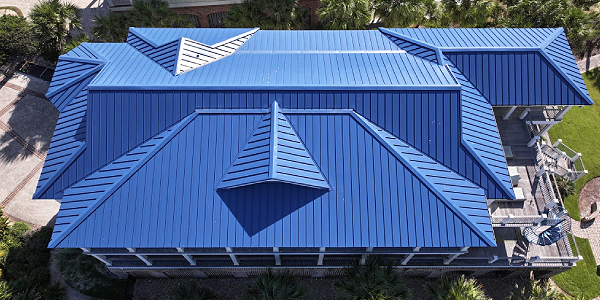

Metal roofs might save the world: Part 2

By Rick Zand, New Tech Machinery.

From energy efficiency to waste reduction, metal roofing comes with a myriad of environmentally friendly benefits.

Metal roofing has proven itself time and again to be a great roofing choice for those looking for environmentally friendly options. From recyclability and energy efficiency that minimizes waste and conserves resources to a long lifespan of 50 years or more with minimal maintenance, it’s quickly becoming the go-to roof choice over traditional asphalt shingles that have ruled the residential market because of their price-point.

Further pushing metal ahead of asphalt is its performance in the face of concerns about climate change and natural disasters. In the first part of this series, we saw how a metal roof played a part in saving one Lahaina couple’s home.

At New Tech Machinery (NTM), we're excited to see the growing popularity of metal roofs. We believe the use of metal roofs not only provides benefits to home- and building-owners, but it can also help foster a healthier planet and global community. The environmental benefits of standing seam metal should be a selling point that metal contractors and manufacturers share with prospective buyers.

In this article we’ll look at how metal stands up in comparison to traditional shingles, and reduces the amount of waste ending up in landfills, oceans, and ecologically vulnerable areas.

Asphalt shingles

Asphalt shingles

Asphalt, first produced in the U.S. in 1893, is a byproduct of crude oil. Refining crude oil is a dirty process involving a sobering list of toxins released into the atmosphere. Anyone who’s been around a refinery has witnessed black smoke and scorching flames pouring out of smokestacks as excess gases and impurities burn off. Asphalt shingles are also composed of fiberglass. Petroleum refinement releases greenhouse gases into the atmosphere and fiberglass production releases various toxins as well.

Further, while asphalt roofs are inlaid on one side with mineral pebbles, they don’t contain the reflectivity of metal to keep the structure cooler. Researchers at Yale University found that asphalt, including roofs, emits hazardous pollutants on warm, sunny days, affecting air quality. In fact, not only warmth but solar radiation increases asphalt emissions at a steady rate. Comparatively, the American Iron and Steel Institute reports that producing steel today requires less than half the energy as 40 years ago, resulting in a 50% decrease in greenhouse emissions.

Asphalt doesn’t naturally provide fire resistance, although it can be treated and tested to Class A. However, it’s vulnerable to strong winds and wind gusts, requires more maintenance than metal and doesn’t last nearly as long. While metal costs more, it can save the consumer money in the long run due to tax rebates, reduced energy bills, less maintenance, and longer life.

Metal roof panels

The manufacturing of metal roof panels is significantly more eco-friendly than asphalt. Plus, metal is 100% recyclable, whereas recycling shingles hasn’t really gotten off the ground yet. The 2030 goal is to have about 1% of shingles currently going to landfills each year rerouted to recycling centers. This means that out of the 12 million tons of discarded asphalt shingles, only 120,000 tons will be recycled. Factor in that it takes about 300 years for asphalt shingles to decompose and you get an idea of how they’re piling up in landfills at an unsustainable rate.

Conversely, according to the Metal Construction Association (MCA), 60-80 million tons of steel are recycled annually in the U.S. Some steel products are 100% recycled. MCA cites a 2008 survey stating that aluminum used for flat-rolled construction products, like roof and wall panels, is comprised of 85% recycled material. Further, the process of producing aluminum from recycled materials takes up only 5% of the energy compared to producing it from new material. Copper is, on average, comprised of about 45% recycled material, while over 30% of zinc comes from recycled products.

Metal panels are fabricated from at least 25% recycled material and remain 100% recyclable, even decades later. Metal can be recycled repeatedly, so its use never ends. Moreover, metal is cleaner and produces less waste, especially with a portable rollformer that runs panels on-site. While shingles must be cut, leaving the shavings to pile up, metal is fabricated according to custom measurements, reducing the waste produced.

Energy efficiency and cost savings of metal roofing

Energy efficiency and cost savings of metal roofing

Metal roofs reflect solar radiant heat instead of absorbing it, which can reduce cooling costs by 10% to 25%. This not only promises significant energy savings but also decreases the strain on HVAC systems, increasing a building’s overall energy efficiency. Over time, these savings contribute not only to a lower carbon footprint but also to impressive cost savings.

Metal roofs’ energy efficiency makes them a perfect match for sustainable and net-zero-energy homes and buildings. Net-zero energy (NZE) homes produce as much or more energy as they consume annually, and a metal roof would be one component. NZE homes and buildings would also include energy-efficient appliances, renewable energy sources, continuous insulation, Energy Star doors and windows and more.

While not popular with everyone, NZE homes will appeal to a demographic that’s willing to invest in building green. The sticker price may scare some off, but federal and state tax incentives may be available. Check the University of North Carolina’s Database of Incentives for Renewables & Efficiency® to check the benefits in your state.

Lifespan of metal roofs

Not only is metal 100% recyclable but metal roofs last an average 50 to 70 years, whereas shingle roofs average 15 to 30 years, depending on the climate and type of shingles used. Many homeowners opt for cheaper shingle roofs to save money but end up paying more over time as the roofs need more frequent maintenance and replacement. Premium shingles can last as long as 30 years, but they are two or three times as costly as their less expensive counterparts.

Wood shingles need annual maintenance and are at least as expensive as premium asphalt. Wood shingles can be treated for fire resistance but are nonetheless naturally susceptible to fire, which could cause problems with zoning ordinances and insurance coverage. Depending on the area, some insurers may refuse coverage for structures with wood shingle roofs. Also, wood tends to dry out and crack, and shingles may warp and need replacing.

With standing seam metal roofs, the thicker the gauge, the stronger the roof. The 22 to 24 gauge is sturdy enough for cold climates with a lot of snow. While steel is stronger than aluminum, it costs more and isn’t necessary in most areas.

Metal siding

Metal siding carries the same environmental benefits as roofing — it’s 100% recyclable and, with an R-value of .61, offers resistance against hot and cold air. Moreover, metal siding has made huge leaps in styles and designs. With weathered farmhouse patterns, various wood grains and specialty colors and designs, metal siding offers nearly unlimited options. Like metal roofs, siding is low-maintenance, long-lasting and durable.

From barndominiums to rural structures to contemporary homes and apartment buildings, the demand for metal siding is surging. Not only is it environmentally friendly, but also compliments the appearance of any structure, whether it’s all metal or mixed materials.

What customers should know

Here are some talking points about the environmental benefits of metal:

- Metal is the world’s most recycled material. The ability to completely reuse it helps to limit the reliance on raw resources and reduces landfill waste.

- Life cycle assessments of metal roofs consistently show metal is a leading sustainable material for roofs and siding.

- Metal reflects solar radiant heat, keeping structures cooler on hot days and reducing energy costs by 10% to 25%.

- Metal lasts 50 to 70 years on average — decades longer than standard shingle roofs.

- Metal is naturally fire-resistant and requires very little maintenance.

- Metal is cleaner to produce, and doesn’t leave the carbon footprint of asphalt which, as a petroleum product, has very limited recycling capacity.

While asphalt shingle roofs are undoubtedly cheaper, we hope that your customers begin to value metal for its many environmental benefits and how it will serve them in the long run with less maintenance costs, increased reflective properties, energy efficiency and longer life.

Original article and photo source: New Tech Machinery

Learn more about New Tech Machinery in their Coffee Shop Directory or visit www.newtechmachinery.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In