UP TO THE MINUTE

Calculating the R-value of insulation

April 22, 2025 at 6:00 a.m.By Drexel Metals.

Having a high R-value is critical in determining a material’s insulation capabilities, a necessity for optimizing energy efficiency. Industry experts break down the calculation process of a building material’s R-value.

In building for a greener, more energy efficient tomorrow, it’s vital to take into consideration the accurate measurements of building materials’ resistance to heat flow. This measurement, called the R-value, is a significant figure in relation to making sure a project is optimized for maximum energy efficiency.

Building designers, architects and contractors rely on the R-value often, especially in the case of determining the most effective insulation options for their projects. The higher the R-value, the better the insulation power of that material. To enhance a building’s thermal performance, many building teams employ polyisocyanurate (polyiso) insulation. This closed-cell, rigid foam board has one of the highest R-values per inch compared to other insulation products, including mineral wool insulation.

But how exactly is the R-value of polyiso or any other building material measured? The experts at Drexel Metals break it down.

How is the R-value of a building product tested and measured?

To determine a material’s R-value, a full-thickness sample is placed between two temperature-controlled, air-impermeable plates — one hot and one cold. According to the ASTM C518, Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus, heat flow is then measured as it moves across the sample as the temperatures of the plates are maintained. The mean temperature is the average between the temperatures on both sides of the testing mechanism (the temp of the cold side plus the temp of the warm side, divided by two). For example, if the cold side is 65°F and the warm side is 85°F, the mean temperature would be 75°F.

Understanding mean temperature as it relates to R-value

It is important to understand the definition of mean temperature as it relates to the R-value calculation. Mean temperature is critical because a material’s R-value can vary with changes in the temperature at which it is measured. It can differ between very cold or very hot temperatures. To ensure consistency, the Federal Trade Commission (FTC) established requirements for R-value to be measured at a standardized mean temperature of 75°F. The uniformity enables accurate comparison between different insulation products. Straying from this FTC requirement is a deliberate attempt to mislead and confuse building owners or project teams, which could result in improperly insulated buildings.

It is also important to note that mean temperature is not synonymous with ambient temperature or outdoor temperature. For instance, if the indoor temperature of a building is 65°F year-round, it does not represent the mean temperature. Rather, 65°F would represent either the “warm side” or the “cold side” during the test.

In real-world scenarios, building components in major U.S. metropolitan areas are typically exposed to average mean low temperatures above 50°F. Similarly, average mean high temperatures range from the low 60s to the upper 70s, depending on the geographic region.

Conclusion

Given that the R-value of an insulation material directly impacts a building’s ability to maintain comfortable indoor temperatures, polyiso can help project teams achieve optimal thermal efficiency. Polyiso also resists air and moisture intrusion, further supporting building performance.

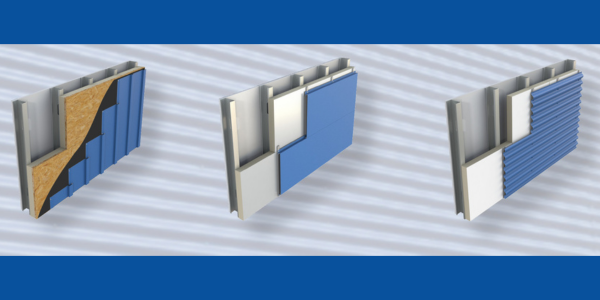

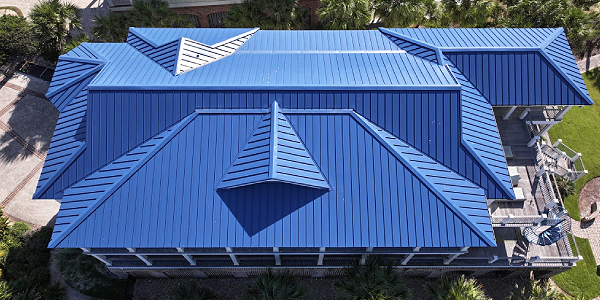

Looking to leverage polyiso’s high R-value in your next project? Consider Defend-R from Drexel Metals, a complete line of roof and wall insulation panels that feature a closed-cell polyiso foam core manufactured to various facer types for ultimate performance in different applications.

Original article and image source: Drexel Metals

Learn more about Drexel Metals in their Coffee Shop Directory or visit www.drexmet.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In