UP TO THE MINUTE

Snap lock versus mechanical seam

By Rick Zand, New Tech Machinery.

Understand the differences between standing seam metal roof profiles.

In the metal roofing world, standing seam is a popular option due to its durability, weather resistance and clean aesthetics. Identifiable by the interlocking panels that run vertically from a roof’s edge to eaves, standing seam is used on both residential and commercial buildings. There are generally two types of standing seam metal roofs — snap lock and mechanical seam profiles. Each type has unique design features, installation needs and regulations around them that must be understood before starting a project.

At New Tech Machinery, we have decades of experience with standing seam roofs. Our portable rollforming machines and profiles for standing seam roofs (which includes snap lock with slotted flange, mechanical seam trapezoid and SSQ 275, our snap-lock/ mechanically seamed proprietary profile) means that we know a bit about choosing the right type of standing seam for your project.

Keep reading to learn more about the profiles, requirements and performance of standing seam! You also will learn about New Tech Machineries standing seam roof panel machines, the SSR MultiPro Roof Panel Machine, SSH MultiPro Roof Panel Machine and SSQ II Multipro Roof and Wall Panel Machine. Our Roof Panel Machine Quiz can help you discover which machine is right for your operation.

Snap lock versus mechanical seam profiles

The primary difference between snap lock and mechanical seam panels lies in their installation and seaming methods.

Snap lock panels have pre-formed edges that snap together without the need for special tools, making installation faster and simpler. They are suitable for roofs with a pitch of 3/12 or greater.

Mechanical lock panels, on the other hand, require special equipment to crimp the panel edges together, which increases the material and labor costs. However, this crimping process creates a tighter seal, making mechanical seam panels more appropriate for low-slope roofs or harsh weather conditions. They can be installed on roofs with a minimum slope of .5/12, depending on the seam height and specific product design.

Two types of mechanical seam panel profiles

1 - Single lock profiles: Single lock refers to a 90-degree single fold in the seam. It’s easier to install and performs well in milder environments.

2 - Double lock profiles: Double lock mechanical seam profiles refer to the 180-degree double folded seam. They are well suited for low-slope roofs in extremely wet environments, as the double fold provides extra fortification to the seam. They’re also preferable in cold weather climates that experience freezing and thawing, where the double lock seam will hold up better than the single lock. However, installation is more labor intensive, increasing the price and making damaged panels more difficult to replace.

Snap lock and mechanical seam testing and uplift requirements

Testing plays a crucial role in determining the appropriate type of panel for a specific project, especially for commercial and industrial work. Standing seam metal roofs undergo rigorous testing to ensure they meet the required standards for uplift resistance, water penetration and air infiltration. These tests help dictate which panel type, seam height and panel width are suitable for a particular building’s specifications and geographical location.

The choice between snap lock and mechanical seam systems may depend on specific project requirements and standards, such as those set by the International Building Code (IBC) or local regulations.

Uplift resistance is particularly crucial in areas prone to high winds. Uplift testing measures how well the roofing system can withstand upward forces. The corners take the brunt of the wind current, followed by the perimeters (roof edges) and finally, the field or internal and center, part of the roof.

Panel design, seam type and clip spacing play significant roles in determining a roof’s uplift capability. If your panels are holding up well to the uplift pressures and the project requirements aren’t too strict, you might be able to use one clip spacing across all roof areas.

However, if you must meet higher design pressures, you might have to use tighter clip spacings in different zones closer along the corners and perimeters and further apart on the roof field. Ultimately, it’s essential to choose a system that meets the uplift requirements for the building’s codes and design criteria.

Panel width and seam height

The width of the panels and the height of the seams can also influence the roof’s performance. Wider panels and higher seams may enhance the roof’s ability to shed water. However, the choice between different panel widths and seam heights will depend on the architectural design, aesthetic preferences and specific building requirements. Here are some height and slope considerations:

- Seam height: Seam height, also known as rib height, can play a factor based on the slope of your roof. Water shedding roofs (hydrokinetic, above a 3/12) can usually perform well with a lower seam height. Water holding roofs (hydrostatic, below a 2/12) will usually require a taller seam height to help protect against water infiltration and raise the seam to prevent it being overrun by water. Standard seam heights for standing seam metal roofs vary from one to three inches, with 1½” and 2″ being the most common sizes. A higher seam height generally offers better leak resistance, especially crucial in areas with heavy rainfall or snow. In contrast, lower seam heights may cost less but offer reduced protection against water penetration.

- Slope or pitch: As mentioned, a minimum slope of 2/12 is usually required for standing seam metal roofs, meaning the roof must rise at least 2″ for every 12″ of horizontal span. This minimal slope ensures effective water runoff and prevents pooling, which can lead to leaks and damage. However, steeper slopes can enhance the aesthetic appeal and efficiency of rainwater shedding. Installing mechanical lock panels below 2/12 in steel requires continuous in-seam sealant to adhere to ASTM E2140 testing standards.

- Climate influence: Geographic locations can play a significant role in determining the proper panel selection. For instance, areas with high wind uplifts will require a panel tested to perform in those conditions, while an area with heavy snow accumulation throughout the year might be better suited with a mechanically seamed panel.

- Compliance with building codes: It is crucial to adhere to local building codes and regulations, which may have specific minimum slope requirements for standing seam metal roofs to ensure safety and performance standards are met.

Ultimately, selecting the right combination of seam height and slope is essential for optimizing the performance, longevity and aesthetics of standing seam metal roofs. It’s also important to ensure that your roof meets all necessary requirements and is suitable for your local climate and building codes.

Installation and cost considerations

While snap lock systems are generally easier and quicker to install, mechanical seam roofs offer greater durability and protection for certain applications, making them suitable for more demanding environments. The choice between the two can also be influenced by budget constraints, as mechanical seam systems typically involve higher material and labor costs due to the complexity of installation.

Standing seam aesthetics

Aesthetics can also play a role in choosing between snap lock and mechanical seam systems. Snap lock panels tend to have bulkier seams, which might not be suitable for all architectural styles. In contrast, mechanical seam panels offer a sleeker look with thinner seams, which may be preferred for residential applications or when matching the roofing style of adjacent buildings.

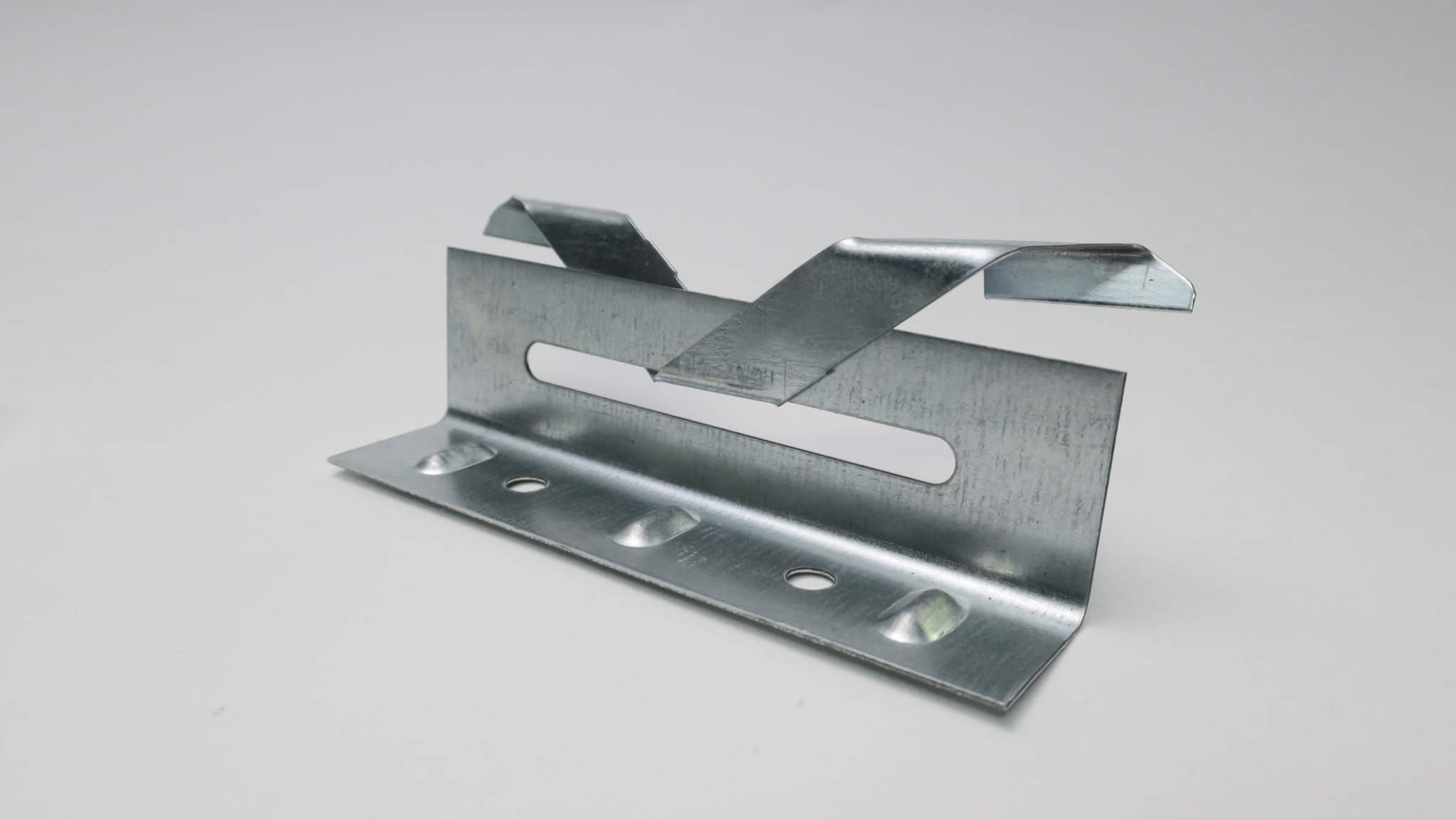

Understanding two-piece expansion clips and fixed clips

In the realm of standing seam metal roofing, the method of attaching panels to the roof deck is a critical aspect of the roof’s overall performance and durability. Two main types of clips are used in the installation of standing seam roofs: two-piece expansion clips and fixed clips.

Two-piece expansion clips

Two-piece expansion clips consist of two interlocking components that allow for thermal expansion and contraction of the metal panels. The base of the clip is fastened to the roof deck, while the top/tab attaches to the metal panel. This design permits the panel to move along the clip’s length, accommodating the natural expansion and contraction of metal due to temperature changes without warping or damaging the panel.

This ability to move can help prevent oil canning or the visible waviness in the flat areas of metal roofing and wall panels. By allowing for thermal movement, two-piece expansion clips help maintain the roof’s aesthetic appearance and structural integrity over time, as the seams expand in hot temperatures and contract in cold temperatures. These clips are especially crucial for long panel runs where significant expansion and contraction can occur.

Fixed clips

In contrast, fixed clips rigidly secure the metal panels to the roof deck and do not move with the panel t. These clips are cheaper than their two-piece counterparts but come with limitations. Fixed clips are suitable for shorter panel lengths, generally not exceeding 20′ for mechanically seamed panels, to minimize the risk of oil canning and panel distortion due to thermal expansion. Fixed clips are standard for snaplock panel systems as snaplock systems are designed to accommodate thermal movement independent from the clip.

While fixed clips offer a cost-effective solution for certain applications, they are not recommended for areas subject to wide temperature fluctuations or for roofs with long panel runs. The lack of movement can lead to the panels buckling or becoming distorted over time, especially as the metal expands and contracts.

Choosing the right clip for a standing seam roof

The choice between two-piece expansion clips and fixed clips depends on various factors, including the engineering requirements for the project, the climate, the length of the metal panels and the overall design requirements. For commercial projects and areas with significant temperature changes, two-piece expansion clips are generally preferred due to their ability to accommodate thermal movement. However, for smaller residential projects or roofs with shorter panel lengths, fixed clips may be a suitable and more economical option.

Ultimately, the selection of the appropriate clip type is an essential part of the roofing system’s design and installation process, impacting the roof’s aesthetic, functionality and longevity.

So how do I plan a job based on this information?

When planning a standing seam metal roofing project, it’s essential to evaluate factors such as roof slope, local weather conditions, testing requirements and aesthetic preferences. Both snap lock and mechanical seam systems have their advantages and suitable applications. By understanding the specific needs and constraints of your project, you can select the most appropriate standing seam metal roofing system to ensure longevity, performance and visual appeal.

Keep in mind, the requirements for commercial projects will probably be more stringent than for residential projects. If you’re servicing an area that experiences high wind or extreme weather, you’ll need to plan for those factors. A metal standing seam roof meant to last 60 years isn’t much good if it blows off during the first tropical storm.

The most important consideration is what is going to most benefit your customer. Everyone wants to save money on projects but explaining the value of a stronger roof using the right standing seam and pricier two-piece expansion clips might save them more in the long run if they’re living in a region that experiences extreme climate conditions.

With the 16 panels available to SSQ II MultiPro Roof and Wall Panel Machine owners, New Tech Machinery offers the SSQ275 profile, a proprietary tooling that can be used for both snap lock and mechanical seam. For more information on NTM metal panel and gutter machines or any of our profiles or accessories, visit our machines page.

Original article and image source: New Tech Machinery

Learn more about New Tech Machinery in their Coffee Shop Directory or visit www.newtechmachinery.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In