UP TO THE MINUTE

Metal roofing: Sustainable from start to finish

By Drexel Metals.

Metal roofs shape a sustainable future for the building industry, from material efficiency to lifecycle longevity.

The energy demands and environmental impact of the U.S. construction industry are evolving. Contributing to about one third of energy consumed, greenhouse gas emissions and raw materials used and waste created, architects and builders are trying to embrace a greener ethos, adhering to LEED certification, the Living Building Challenge, the 2030 Challenge and more with the goal of reducing the environmental impact of the industry.

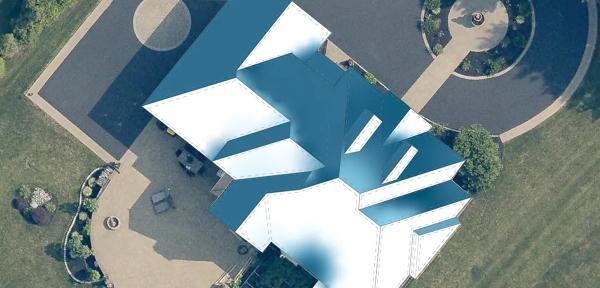

One way contractors are contributing to a more sustainable future is by using metal roofing. Beyond its aesthetic and durability, metal is a testament to sustainability from start to finish. With the ability for panels to interlock using standing seams, metal roofs eliminate the need for a penetrating fastener, which can help improve the energy efficiency of a building. They are also a sturdy platform for solar panels, another sustainability option for building owners. However, solar panel compatibility is far from the only sustainable benefit of choosing a metal roof. Metal roofs offer several ecological benefits from the time they are installed until they are replaced.

Before installation

Metal roofing panels are made from 30 – 60 percent recycled content. This lowers the energy needed to create the coils and panels, reduces greenhouse emissions, and diverts waste from landfills. The recycled content of metal roofs can be used toward LEED credits focused on recycled materials, including Materials and Resources (MR) Credit 4.1 for Recycled Content.

In addition to recycled content, metal roofs can be painted in a variety of colors prior to installation, the majority of which are cool roof rated. Cool roofs are highly reflective and efficiently re-emit any heat they absorb. For example, some of Drexel Metals’ offerings can reflect and re-emit solar radiation by up to 90 percent. Trapping less heat and cooling down quickly, these roofs are a vital part of energy-efficient and sustainable building practices.

During installation

When it comes to installation, metal roofs are, on average, 50 – 75 percent lighter than other roofing systems. Not only does this sideline structural issue that could require costly workarounds, but it also translates to a lower carbon footprint by requiring less fuel and emissions to ship. Lightweight metal coils and sheets are also able to be efficiently packed and safely shipped with fewer truckloads, further reducing the energy needed to move them from manufacturing plant to jobsite. This method of shipping also reduces the chances of damaged product, which means even fewer shipments.

When the materials arrive onsite, contractors can use portable roll-forming machines to increase productivity and sustainability. This process reduces lead time and produces less waste for a build that supports lean construction practices without sacrificing quality.

The sustainability of a lightweight material that can be fabricated onsite is further aided by Drexel’s cross-country reach. With manufacturing facilities from Portland, Maine, to Portland, Oregon, Drexel can provide efficient shipping and fabrication support to help any project achieve its green building goals.

After installation

Metal roofs can also last 50 – 70 years, depending on the material and location. Their lifespan is more than double that of other roofing materials. Needing to replace their roof less often, building professionals and homeowners not only save money but also reduce the amount of building materials needed to ensure a safe and habitable space. This translates to less energy consumed to make, distribute and install a roof, as well as fewer greenhouse emissions and waste overall.

When a roof has reached the end of its service life, it is fully recyclable to create a sustainable circular economy. Further, building professionals and homeowners can also potentially receive scrap credit from an installer when they choose to recycle their old roofing systems.

Now what?

As the construction industry pushes for more sustainable building practices across the board, it is important to identify all the ways buildings can be made more ecologically conscious. Metal roofs are just one part of the sustainability puzzle. They can lower energy consumption with recycled content and cool roof ratings. They can reduce carbon emissions by streamlining shipping and fabrication processes. They can even decrease the amount of scrap in landfills with their long lifespan and total recyclability. With such benefits, metal roofs beg the question, “What other ways can we make construction more sustainable?”

Original article source: Drexel Metals

Learn more about Drexel Metals in their Coffee Shop Directory or visit www.drexmet.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In