UP TO THE MINUTE

Counter high winds with perimeter edge metal

By Chicago Metal Supply.

Learn more about perimeter edge metal and how it can better protect your commercial roofing projects!

When working on commercial roofs and other low-slope projects, wind can cause quite a few problems in even the best laid architectural plans. While wind is a concern for all roof projects, commercial roofs are particularly vulnerable to the high pressures these winds can place on a roof. In the worst scenarios, this causes the roof to lift in areas experiencing tremendous force, which subsequently exposes the structure underneath the roof. This can lead to issues like water damage that can compromise the entire building’s structure.

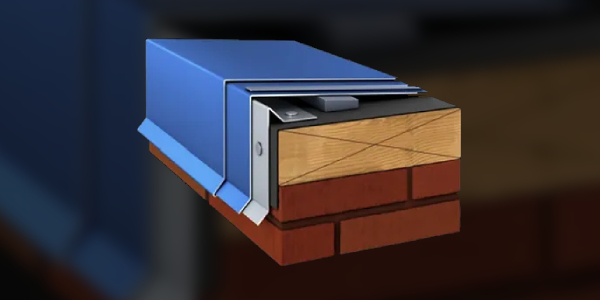

In many cases, it has been found that the damage from the wind begins on the roof’s perimeter. Essentially, high gusts slip through gaps along the edge of the roof and then shoot towards the middle of the roof, lifting and damaging as they go. Thankfully, here at Chicago Metal Supply, we have a simple solution to this problem — perimeter edge metal systems!

What does perimeter edge metal do?

There are two main reasons to install perimeter edge metal. On one hand, it enhances the aesthetic of its respective roof, helping it stand out among the others. On the other hand, it reduces the effect of wind, preventing it from flowing underneath its corresponding roofing and ripping it up.

From both a functional and aesthetic standpoint, perimeter edge metal is extremely beneficial. It will attract more attention to your roof (and your building as a whole), while also prolonging your roof’s lifespan.

Types of perimeter edge metals

Perimeter edge metals come in many forms, each of which has something different to offer in terms of overall functionality and aesthetic. The kind of edge metals you choose can have an impact on your roof’s performance and can also affect your future warranty claims.

Made from heavy-duty metals

Here at Chicago Metal Supply, our perimeter metals are designed to withstand substantial wear and tear. Made out of heavy-duty metals and constructed with great precision and detail, they can handle every element from wind to rain, to ice, to snow and more.

We feature certain profiles that are tested to meet the ES-1 standard. This is a standard devised in collaboration between the American National Standards Institute and the Single Ply Roofing Industry — also known as ANSI and SPRI, respectively. Testing requires that all perimeter metals be subject to physical pulling. This pulling simulates natural wind conditions and, if successful in damaging a perimeter metal, will prevent the metal from achieving ES-1 status.

In short, our perimeter metals are of the highest quality. Solid, tough and durable, they are made to thrive for years to come.

Available in a number of colors and metal types

Regardless of the aesthetic of your building, our perimeter edge metals will accommodate you. They’re available in a wide range of colors and can bring out the best in any property. They are also available in a variety of thicknesses and types (steel, aluminum, copper, etc.).

Original article source: Chicago Metal Supply

Learn more about Chicago Metal Supply in their Coffee Shop Directory or visit www.chicagometalsupply.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In