UP TO THE MINUTE

Comparing and Contrasting: Exposed vs. Concealed Metal Panel Systems

By Cayden Wemple.

Check out the pros and cons of exposed and concealed metal panels in this insightful guide courtesy of McElroy Metals.

Pros

The main advantage of concealed fastener panels is their visual appeal. They offer a neat and uncluttered appearance that many building owners find appealing. Designers also appreciate the creative freedom that comes with combining panels of various sizes, shapes, and colors to create unique and artistic designs. Horizontal installation of these panels is also possible, providing a distinctive and upscale feel at a more reasonable cost than other options. The flexibility to mix vertical and horizontal panels further enhances the visual interest of the design.

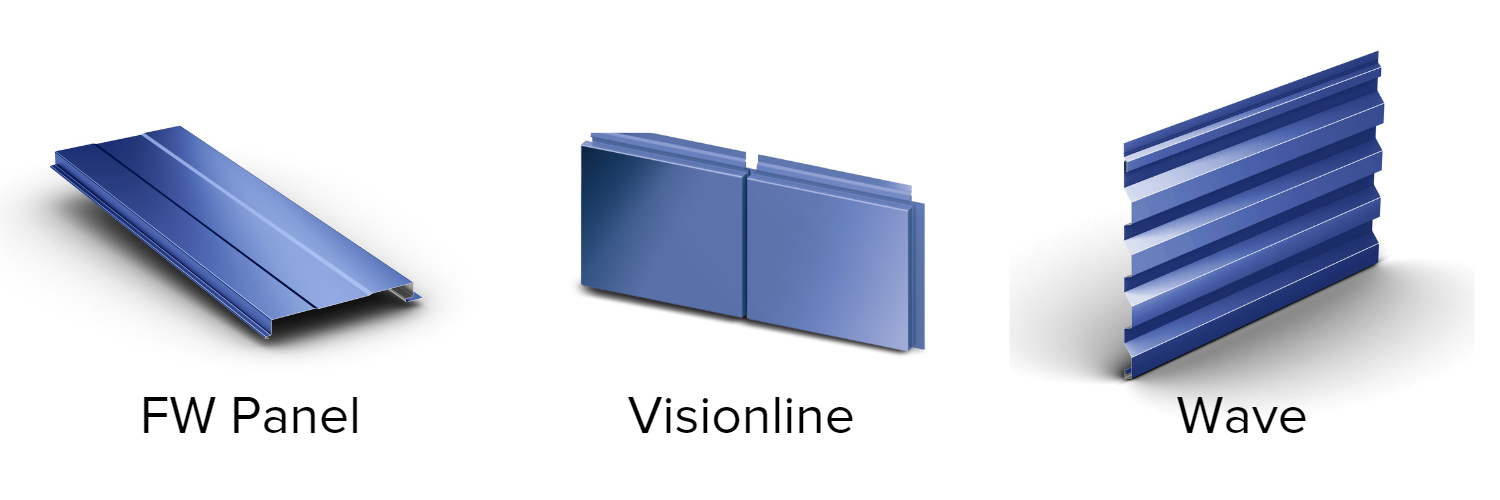

There are vast differences in shape options with concealed fastener panels compared to exposed fasteners.

One of the advantages of concealed fastener panels is that they reduce the risk of leaks at fastener locations. Visible fasteners pose a small risk, and many building owners prefer to avoid it. Exposed fasteners require maintenance due to gasketed washers, but concealed fastener panels don't. Concealed fastener systems also offer improved security for building owners.

Cons

Despite their benefits in terms of aesthetics, design flexibility, security and maintenance, there are a few reservations to consider when choosing concealed fastener panels. One of the primary concerns is the cost, which is higher than that of exposed fastened panels, even though it is still significantly lower than other product options. The narrower width of the panels and reduced cover width can also impact both the cost of the product and installation. Additionally, concealed fastener panels typically require solid wooden crates for shipping, which can add to the cost of the product and increase freight costs due to the extra space needed during shipping.

Concealed fastener panels have some limitations, despite their appeal to building owners seeking a sleek appearance and reduced maintenance.

One drawback is their higher cost compared to exposed fastened panels, which may make them less attractive to some buyers. Additionally, the narrower panel width of concealed fastened systems can increase installation costs and time required for completion.

Oil canning can also be an issue with concealed fastener panels, especially if the substructure is not level or smooth. This can result in unappealing visual imperfections.

Finally, repairing concealed fastener systems may prove challenging due to their interlocking design, which can complicate modification efforts. In contrast, exposed fastened panels may be easier to repair or alter.

Learn more about McElroy Metal in their directory or visit www.mcelroymetal.com.

About Cayden

Cayden is a reporter for RoofersCoffeeShop, MetalCoffeeShop and AskARoofer. When he isn’t writing about roofs, he’s usually playing guitar or writing songs for his musical endeavors.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In