UP TO THE MINUTE

Best practices for your metal roofing needs

By Sheffield Metals International.

Make sure you are practicing all of these tips so that your metal roofing panels are taken care of.

You might not give much thought to handling metal roofing panels but doing it right can make all the difference. Improper handling can lead to kinks, dents or scratches, rendering panels unusable before they even make it to the roof. Imagine the ripple effects: lost time, money and effort.

Jump into this guide from Sheffield Metals International to ensure your metal roofing project goes off without a hitch, preserving both the aesthetics and functionality of your investment.

Handling metal roofing panels & trim

You might be asking yourself why it’s essential to properly handle standing seam metal roofing panels. There are several reasons, primarily because incorrect panel handling can cause:

- Kinks, dents or unsightly bends in the panels – If you move the panels too roughly or without proper support, the panels can dent and bend in ways they are not intended to. If the kink or bend is bad enough, it can warp the panels and make them unusable in the installation.

- Oil canning (or increase the likelihood of oil canning) – Oil canning is defined as the perceived waviness of a metal panel and is an inherent characteristic of light-gauge, cold-rolled flat metal products. In other words, it’s a visual phenomenon that makes metal panels look wavy or somewhat distorted, especially in the broad, flat areas of a metal roof or wall system. Improper moving, twisting and handling of panels can allow for more oil canning opportunities.

- Scratches or gouges that go down to the metal core – If a panel is dropped when one or more crew members are handling it, it can be severe enough that a scratch or gouge goes through the paint or coating system and reaches the metal core. If this happens, it can void your paint/substrate warranty before even installing the roof. Remember that the coating is very thin at around 1 mil (or 0.0254 mm), so dropping a panel can quickly leave the coating damaged and difficult to remedy with a paint pen.

- Other miscellaneous other damage to the panels before it ever makes it up on the roof

In short, improper handling of the panels can result in irreversible damage, which leads to lost time, effort and profits.

Best method(s) of handling metal roofing panels

The proper method for carrying every single metal roofing panel doesn’t exist, but there are some best practices to always make sure you follow:

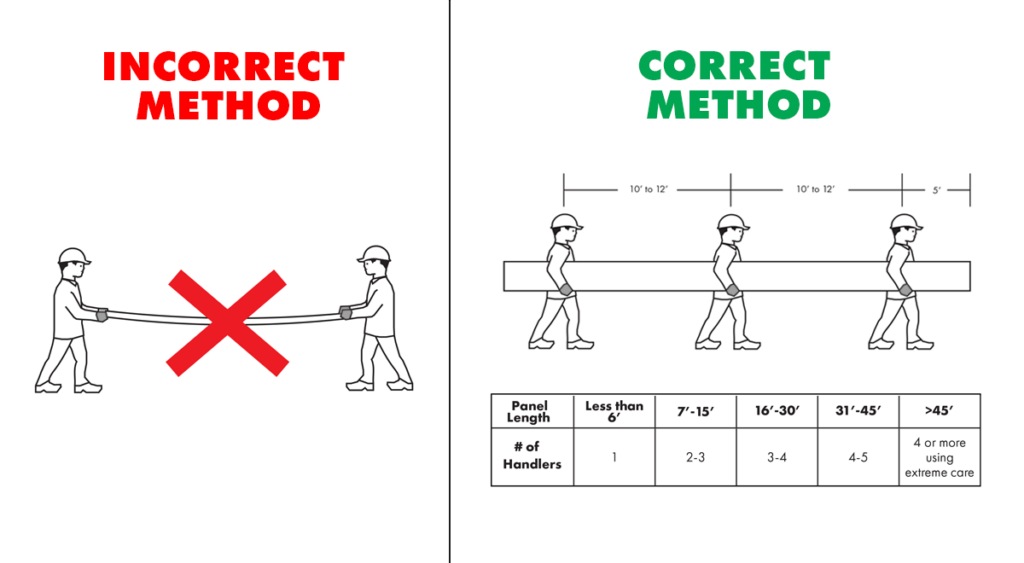

The number of people required to move and handle a panel directly relates to the length. Below is a photo illustrating how to carry a panel; you essentially should have:

-

Under 6 feet: 1 handler

-

Between 7 and 15 feet: 2 to 3 handlers

-

Between 16 and 30 feet: 3 to 4 handlers

-

Between 31 and 45 feet: 4 to 5 handlers

-

Over 45 feet: 4 or more handlers (while practicing extreme caution not to let the panel sag, bend, kink or drop)

- Where more than one handler is recommended, each handler should be 10 to 12 feet apart, and the first and last handlers should be approximately 5 feet from the ends.

- The panel should be carried on its side, where the flat part of the panel is perpendicular to the ground.

-

Carrying panels on the side create more rigidity and makes them less likely to bend, especially in the flat area.

-

We also recommend supporting the panel from the bottom and not carrying it from one of the seams.

- Regarding personal protective equipment (PPE), it’s best to wear cut-resistant gloves.

-

As most installers know, rollformed panels can have sharp edges and points, so the best way to protect your hands is to have cut-resistant gloves.

-

Gloves are critically important when handling zinc and copper panels, as these panels can easily stain from the natural oils on human skin.

-

Panels should be moved one at a time, or two at a time if short enough.

-

Depending on the length of the panels, there are some instances where installers can move two at once. If you feel comfortable moving two panels, ensure the coated sides are facing each other and exercise extra caution so the panels do not cause damage to one another.

-

Once you’ve reached the area you’re moving the panels to, ensure you do not lay directly on the ground. Instead, place the panels on a supporting surface with care.

-

Do not lay panels directly on the ground. You can never be sure what is on the ground and if anything (such as gravel, grass, concrete, etc.) could negatively affect the panels.

-

Support the whole panel length using pallets, two by fours, or another method where the panels are not touching the ground.

-

Always take the PVC film off the panels after rollforming, but before panels are installed.

-

You can keep the PVC film on while handling panels to provide an extra protection layer. However, do not forget to remove it before the installation.

-

Additionally, the PVC film should always be taken off before any level of exposure to UV or extreme heat.

-

Specifically, you should remove PVC film before any ultraviolet (UV) or extreme heat exposure. PVC on panels exposed to UV light, moisture or both can break the PVC down, making it difficult to remove and/or leaving adhesive residue on the painted metal surface.

-

To get the panels up to the roof deck, you can:

-

Hand them up individually using the perpendicular panel handling method (with as many people safely supporting the panels as possible).

-

Use a forklift or crane to lift the panels to the roof plane (ensure the full panel length is still supported and not bending the ends downward).

-

Lift the rollformer up to the roof height and rollform the panels directly onto the roof deck. This can be difficult to accomplish because it requires several moving parts, but it does remove many of the issues that can occur because of improper panel transporting or handling.

Best way to store metal roofing panels

Like handling them, there are proper ways to store panels as well. And the reasons for adequate storage of rollformed panels are similar as well, as improperly storing panels can:

-

Lower the quality of the panels – There are several ways that improper storage can lower the panel’s quality. One of the significant concerns of incorrectly storing panels is moisture getting on the cut edges of the panels and creating issues with the paint and metal substrate. Another concern is air circulation, as little access to airflow is not good for the metal’s integrity and makes it harder for any moisture to dry.

-

Create nicks, scratches or gouges that go down to the metal core – Without the right storing practices, panels can rub up against each other, the ground or other rough items, which runs the risk of damaging, nicking or scratching the paint system on the panel. If this occurs and is severe enough (where it goes down to the metal core), it can void your paint/substrate warranty before the roof is ever installed.

-

Create an unsafe working environment – If panels are being stored all over the place — or in an active working area — this can be a safety concern, especially because rollformed panels have sharp edges. Stacks of stored panels can get in the way of forklifts, production, rollforming and other daily tasks.

-

Cause preventable damage to the material needed to complete installations – Any time material is damaged during storage, it’s a time and money loss that is ultimately preventable.

Proper method(s) of storing metal roof panels & trim

Before we get into some of the best storage practices, it’s critical to note that all panel storage depends on the time frame. If the storage time is only a few days, the recommended conditions are still good to follow but might not be a huge concern. However, if you’re planning to store panels for weeks or months at a time, it’s imperative to follow the best practices below.

- Always store panels in a dry environment with relatively stable temperatures.

- It’s best to avoid prolonged exposure of pre-painted panels to wet or humid conditions, which can cause paint blistering or substrate corrosion, especially at cut edges.

- Significant temperature differences and fluctuations can also cause condensation/moisture to develop on the panels.

- If bundles of nested panels become wet, the panel sheets should be separated, wiped with a clean cloth without delay and then placed so that air circulation completes the drying process. This is true for both painted and unpainted panels.

- Store panels in a spot where there is adequate airflow.

- Airflow is vital for metal, especially if the panels become wet from condensation or other phenomena, as air allows water to dry.

- Panels can be stored in a bundle or a crate; however, you should still verify that air can circulate through the panels.

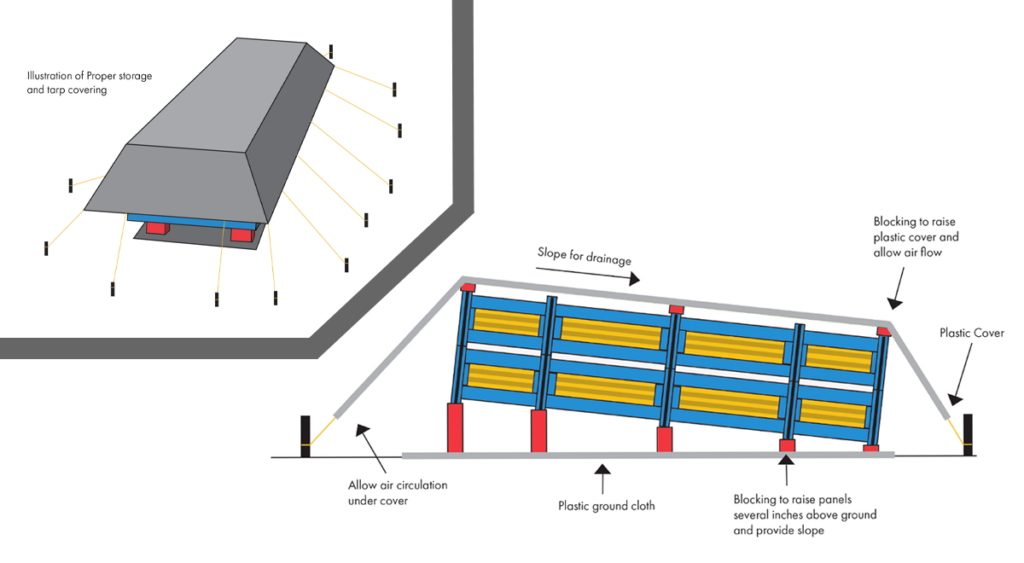

- Store panels under a covering or roof whenever possible.

- If you’re storing the panels outdoors without a roof overhead, it’s best to cover them with a loose-fitting, waterproof tarp to protect the bundle from rain or snow while allowing for air circulation and drying of condensed water. The tarp also shades the bundle from direct sunlight, which helps to moderate temperature extremes and UV damage, and protects the panels from dirt, debris and other contaminants.

- Stacking panels on a roof is sometimes possible, making installation easier. However, you should still follow proper storage recommendations and stay aware of moisture and UV issues if the material is left outside for too long.

- Lay the panels on a surface that supports the entire length of the panels, such as a pallet or two by fours. Do not put them directly on the ground.

- Again, we strongly recommend never putting panels on the ground, as rocks, grass, pavement, etc., can scratch the metal or negatively react with the paint or substrate.

- DO NOT put metal panels on any treated lumber. These two materials can cause an adverse reaction that can degrade the metal and cause premature failure.

- Position the panels in one of two ways: 1.) Fan out the panels with the top panel color side down to protect the coating OR 2.) Stack panels with the color sides facing each other.

- In both scenarios, always stack panels at an angle so any moisture can adequately drain and doesn’t pool on the metal.

- Always use your best judgment when stacking panels, as these stacks should always be manageable (think of the resources, people and machinery that will be moving the panels).

- Secure the panels together when needed.

- If panels are stored loosely on the project site, it is recommended that they be secured together with some type of strapping, i.e., rope or similar. The idea is that if the tarp were to come unsecured, the single panels would not be carried away by the wind.

- Panel bundles that are strapped together should only be unsecured when ready for use.

- Be sure that the strapping used will not scratch or harm the paint finish.

- Be sure to store the panels safely away from people, other items, and commonly used areas.

- As we discussed, storing panels in a bad spot can cause several issues. First, it can create a hazardous working environment for people because panel edges are inherently sharp and can cause injuries. Second, if someone or something bumps into stored panels, stacks something heavy on top of it, runs them over with a vehicle, etc., it can damage the material and render them unusable.

- Constantly moving stored panels opens the door to damage in the process and wastes manpower. It’s best to locate a designated storage area and keep the panels there until they’re ready for use.

- Always take the PVC film off the panels when necessary.

- If you’re in a dry, well-ventilated and temperature-controlled environment, you can keep the PVC film on during storage of the panels to act as an extra layer of protection. However, there are specific environments where you should NOT leave it on, as it may be difficult to remove and leave a residue behind.

- Specifically, you should remove PVC film before any UV light or extreme heat exposure. PVC on panels exposed to UV light, moisture, or both can break the PVC down, making it difficult to remove and/or leaving adhesive residue on the painted metal surface.

- If you’re questioning whether to keep the PVC film on or take it off, it’s best to call the manufacturer for verification.

Final thoughts on how to properly handle & store panels & trim

It’s true: Properly handling and storing metal roofing panels can make or break an installation.

If not done correctly, the material can become damaged or unusable, the integrity of the roof will suffer, crew members could hurt themselves and overall money can be lost.

But these issues can easily be avoided from the start if you know how to handle and store your panels and trim.

Sheffield Metals and our technical department team members are well-versed in the best practices for panel/trim handling and storage, and we regularly answer questions about any environment and location-specific circumstances.

Original article source: Sheffield Metals International

Learn more about Sheffield Metals International in their Coffee Shop DIrecotry or visit www.sheffieldmetals.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In