UP TO THE MINUTE

All parts must work together for a strong roofing system

By Roof Hugger.

Every detail in a roofing system contributes to its overall strength and longevity.

We heard from a client that a competitor in the industry was saying their sub-purlins were stronger than ours here at Roof Hugger. This was mainly due to their "U" shape design, which incorporated more steel and made it seem sturdier. But metal building experts know that the strength of individual parts doesn't guarantee the overall strength of the system.

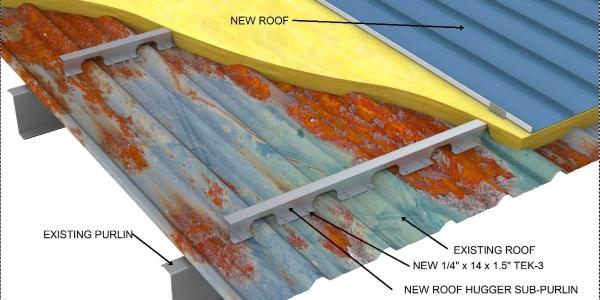

In order to have a strong and durable roofing system, components like purlins, sub-purlins and roof panels must work together. Several factors, such as bay spacing, purlin depth and the types of panels used all play significant roles in determining the system's strength.

While having stronger sub-purlins can be beneficial, if the roof panels, existing purlins or connections fail, the entire system has reached its capacity. Understanding when these failures might occur and identifying the weakest points is crucial. By considering all elements and their interactions, you can avoid system failures and ensure the longevity and safety of your roofing projects.

Testing gives you the hard data about what fails and when. Roof Hugger conducted approximately 20 industry-accepted “AISI S908-08 Gravity Load Base Tests,” numerous “AISI TS-8-02 Uplift Base Tests,” plus additional “ASTM E-1592 Structural Sheet Metal Performance Tests,” Underwriters Lab “UL-90 Tests,” and “Factory Mutual 4471 Testing.”

Roof Hugger, then created software to do a full system analysis of existing and retrofitted strengths to quantify, with certainty, the Roof Hugger System's actual contribution to purlin strength and uplift performance of the new specified panel.

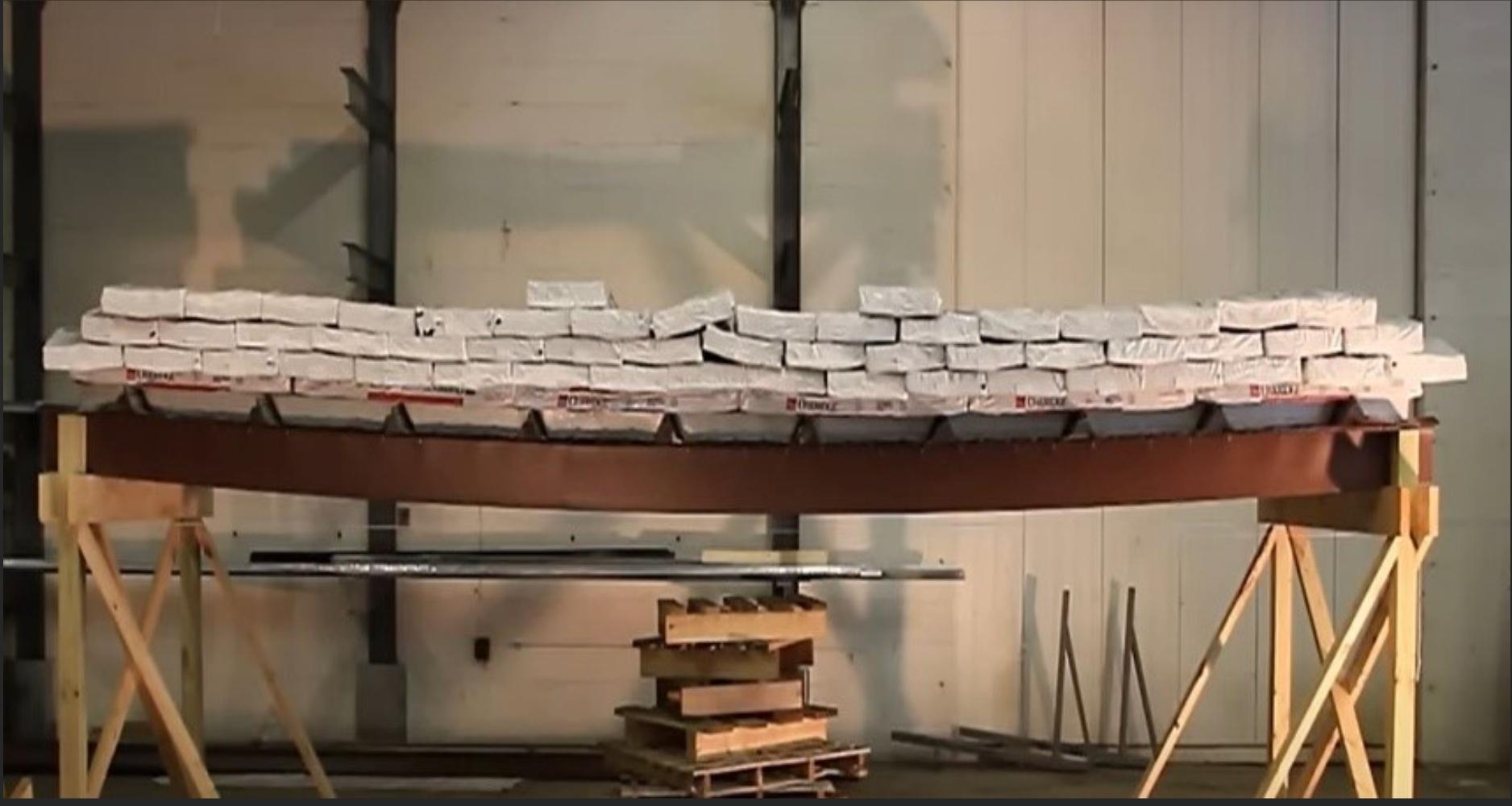

Competitors Non-Industry Standard, Simple Span Test

Hugger Continuous span AISI Purlin testing in 50 ’chamber

Don’t assume the liability of non-industry standard, made for TV, test with unrestrained, simple span purlins with shingles stacked on them to support their purlin strengthening designs.

Roof Hugger has the staff, expertise and solid engineering data that has made it the industry standard in metal over metal retrofit.

Original article source: Roof Hugger

Learn more about Roof Hugger in their Coffee Shop Directory or visit www.roofhugger.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In