UP TO THE MINUTE

McElroy Metal releases new product: Trap-Tee

Trap-Tee is designed to resolve the three major shortcomings of trapezoidal standing seam roof systems: leaking end laps, low wind uplift capability and difficulty in repair.

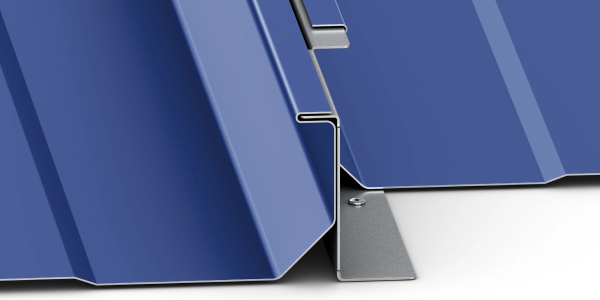

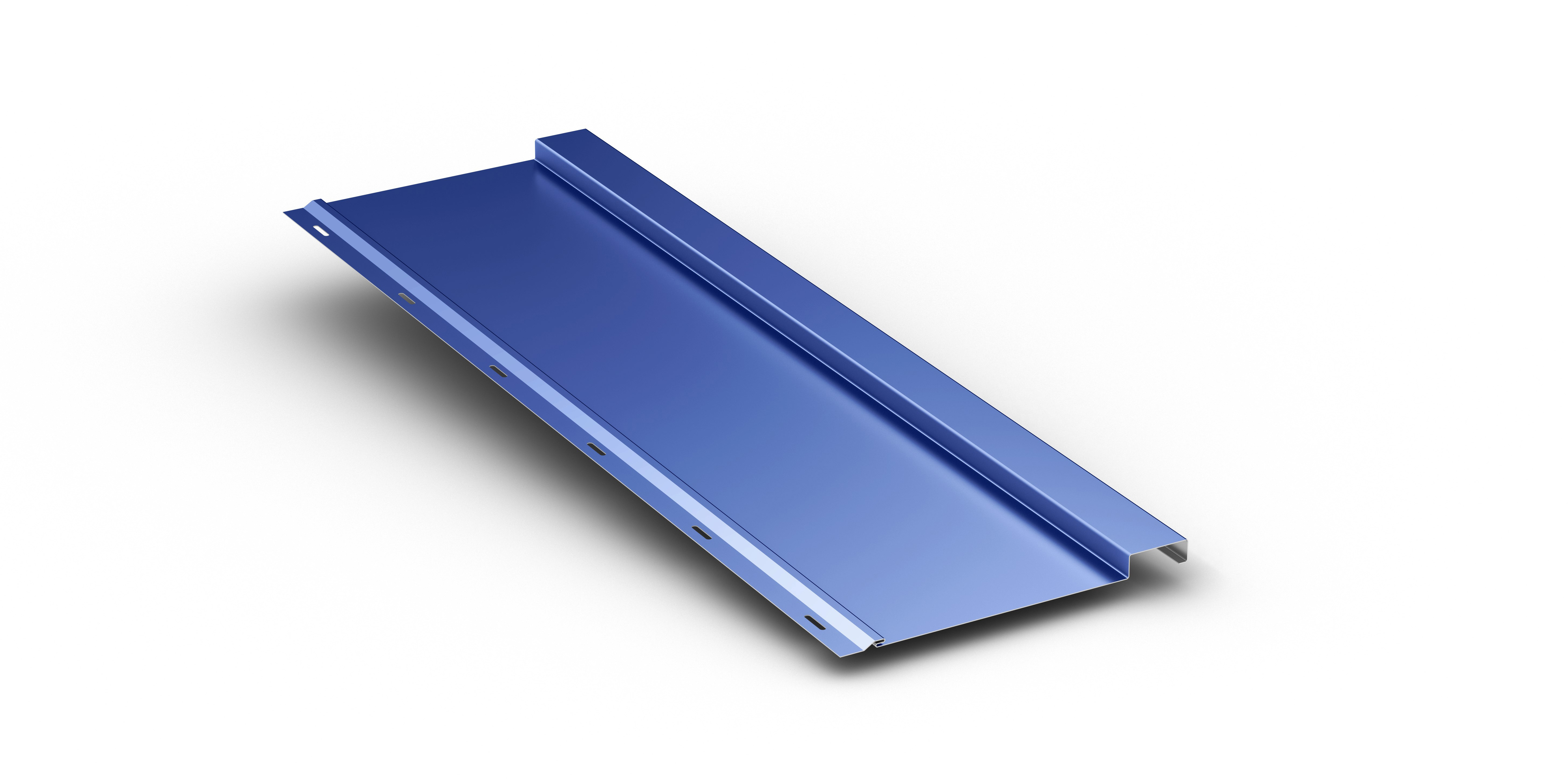

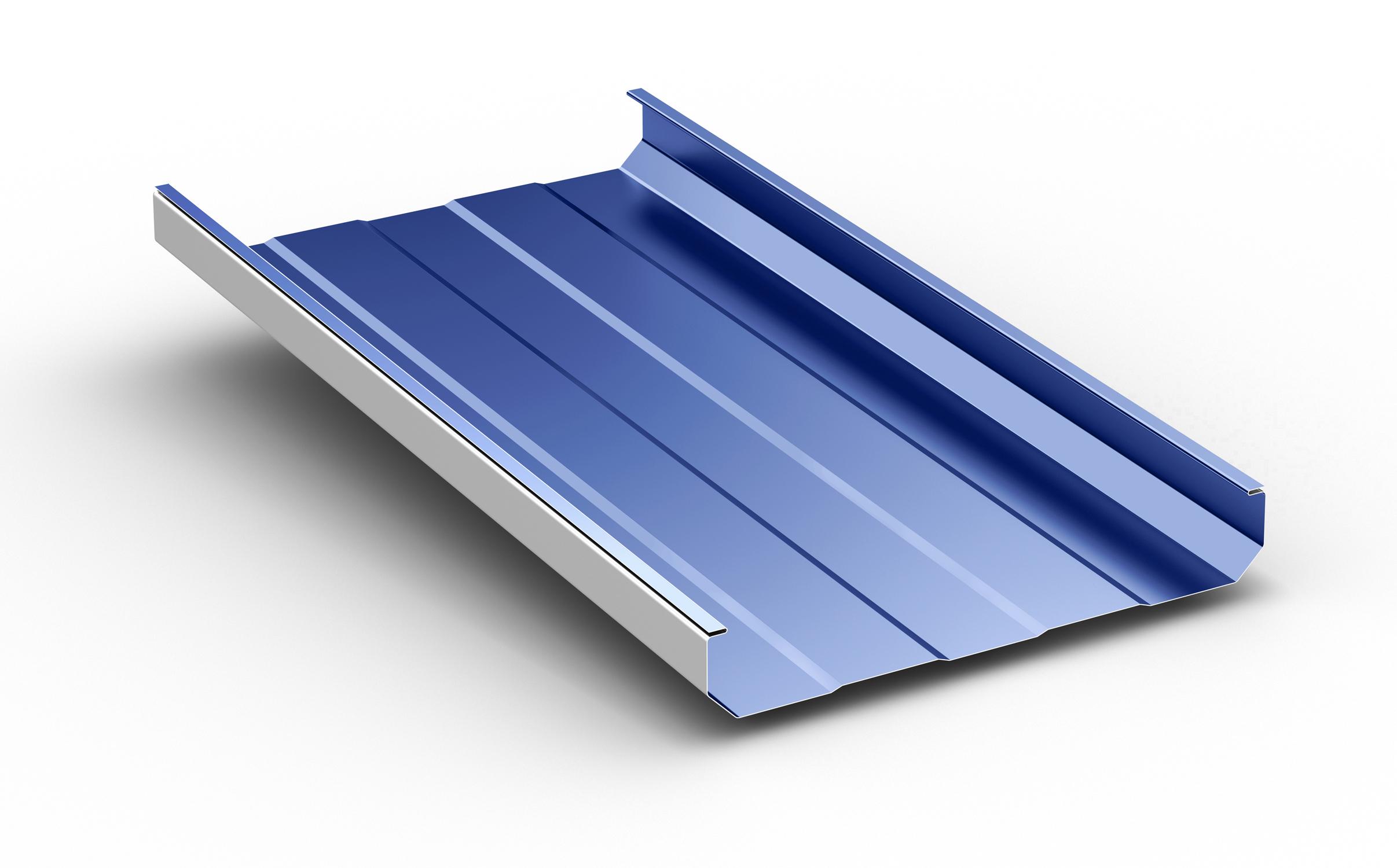

McElroy Metal has released a new product called Trap-Tee. The brainchild of McElroy’s National Recover Manager, Charlie Smith, the Trap-Tee symmetrical metal roofing system is a site-formed, mechanically seamed system measuring 2-3/4 inches tall. Trap-Tee is designed to resolve the three major shortcomings of trapezoidal standing seam roof systems: leaking end laps, low wind uplift capability and difficulty in repair.

Smith created Trap-Tee after visiting a large warehouse that was roughly 860,000 square feet. The building was so big that he could not see from one end of the ridge to the other, was 360 feet from eve to ridge, had an existing 3-inch by 24-inch trapezoidal standing seam and, as he claimed, had “10,000” end lap joints. “As I looked at this roof, I thought this building needs a site-formed, 3” tall, industrial standing seam with no lap joints to leak, with improved wind uplift resistance and is easy to fix or alter after installation,” remarked Smith.

Smith created Trap-Tee after visiting a large warehouse that was roughly 860,000 square feet. The building was so big that he could not see from one end of the ridge to the other, was 360 feet from eve to ridge, had an existing 3-inch by 24-inch trapezoidal standing seam and, as he claimed, had “10,000” end lap joints. “As I looked at this roof, I thought this building needs a site-formed, 3” tall, industrial standing seam with no lap joints to leak, with improved wind uplift resistance and is easy to fix or alter after installation,” remarked Smith.

Site forming eliminates end laps that are vulnerable to leaking and allows the panel to be installed at the same time. This saves a tremendous amount of time and effort and eliminates the need to roof load the panels. The oversized seam and special clips dramatically increase wind uplift capacity and the symmetrical design allows for easy repair or alteration after the roof is installed. Smith stated, “Trap-Tee is an ideal fit when the building owner sees the value in having a roof that should last 50 or 60 years and is easy to repair, with a minimum chance of leaking or blowing off. The system can be applied to new construction, a recover or a remove and replace.” The Trap-Tee system's value dramatically increases when paired with R-Seal rigid insulation on open framing. Offered with Sherwin-Williams® PVDF Fluropon coating, the Trap-Tee has the ability to add curbs, vents, single-panel replacement and even building additions.

Site forming eliminates end laps that are vulnerable to leaking and allows the panel to be installed at the same time. This saves a tremendous amount of time and effort and eliminates the need to roof load the panels. The oversized seam and special clips dramatically increase wind uplift capacity and the symmetrical design allows for easy repair or alteration after the roof is installed. Smith stated, “Trap-Tee is an ideal fit when the building owner sees the value in having a roof that should last 50 or 60 years and is easy to repair, with a minimum chance of leaking or blowing off. The system can be applied to new construction, a recover or a remove and replace.” The Trap-Tee system's value dramatically increases when paired with R-Seal rigid insulation on open framing. Offered with Sherwin-Williams® PVDF Fluropon coating, the Trap-Tee has the ability to add curbs, vents, single-panel replacement and even building additions.

This roof system is specifically designed to go on lower slope rectangular, open frame metal buildings or tilt-up warehouses and attached to purlins, bar joists or a steel deck on slopes down to a ¼” per foot. Existing roof systems have lap joints if the eave-to-ridge dimension is too long to ship and can be difficult to repair or alter once installed. The Trap-Tee has no lap joints and is easy to pull apart and reassemble. It also has extremely high wind uplift capacity using individual and continuous clips in six options. Trap-Tee’s symmetrical T-shaped design makes the panel more watertight because there is no interruption of the seam sealant at the clip location like there is with a double lock standing seam system.

To summarize, there are three main ways Trap-Tee panels are an improvement over other trapezoidal panels:

- No end laps: Onsite panel production for lengths up to 250’ allows most projects to be completed without end laps. Every end lap on a project represents installation time, an opportunity for install errors leading to immediate leaks and end laps that start leaking after 10-20 years of service life.

- Outstanding wind uplift: McElroy Metal specially designed this panel with an oversized seam and special clips, which dramatically increase the wind uplift capacity compared to most other panels in the market.

- Easy repairability: Since standing seam roofs last 60 + years, it’s likely any roof will require some sort of modification during its life expectancy. Whether adding curbs, replacing a few panels or facing building additions, building owners and contractors benefit from the panel replaceability our Trap-Tee panel offers.

Bonus: Offered with Sherwin-Williams PVDF Fluropon coating, the Trap-Tee has a life expectancy approaching 60 years, allowing for the ability to add curbs, vents, single-panel replacement and even building additions.

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer. More information can be found at www.mcelroymetal.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In