UP TO THE MINUTE

Make the Most of Metal Roofing With These Sealants

By Evelyn Witterholt, RCS Reporter.

How can you effectively waterproof any metal roof by using EPDM and butyl sealants?

With metal on the rise as a premium roofing material, many contractors are wondering how to make the most out of the metal roofs they install. Part of the appeal of metal is its durability and weatherproofing qualities. But for a metal roof to be watertight, a proper sealant must be used on all fasteners and attachments, such as solar mounting systems.

Two primary sealants are made of either ethylene propylene diene monomer (EPDM) or butyl tape materials. Here’s the benefits of each and recommendations for which one is best for your next metal roofing project:

EPDM sealants

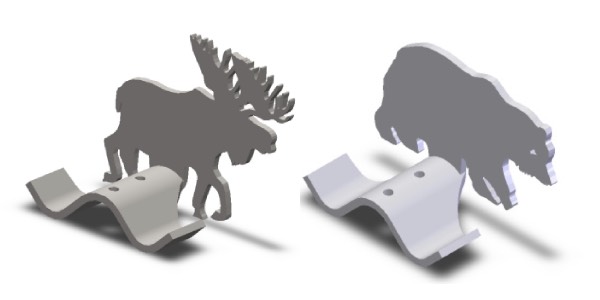

These sealants are made from cured synthetic rubber, and they are known for their strength and flexibility. They can withstand both cold and hot weather and are resistant to moisture. Some solar mounting systems have this gasket type integrated into their brackets, such as the sheeting-only attached brackets from S-5!®. EPDM sealants are built into the brackets specifically for attaching mounting systems above the water plane. This makes it more time-efficient and risk-free for roofing contractors with no guesswork or field application.

Butyl tape sealants

This type of sealant is made from a non-curing isobutylene/isoprene copolymer that forms a waterproof rubber, gummy material. Much like EPDM, it is a flexible material that works well in extreme climates. Again, S-5! offers multiple bracket options with this type of sealant built-in, mainly for attaching solar mounting systems at the water plane.

Which one is best for mounting systems?

Choosing the right sealant for a mounting system on a metal roofing job is largely dependent on the mounting preferences. In the U.S., it’s common to attach a solar mounting system into the flat or low valley of the metal panel. For this preference, you’d want to use a butyl sealant. For other roofing projects, often the penetration point for the mounting system is in the higher point of the profile. In this instance, you’d use an EPDM sealant to attach the system high into the trapezoidal rib of the metal panel.

Additional tips for using sealants on mounting systems

If your goal for the metal roof and its respective mounting system is to be as strong and long-lasting as it can possibly be, here are some tips for using sealants The Right Way™:

- Use factory-applied sealants – As stated above, using fasteners and brackets with these sealant types pre-applied minimizes messy applications and reduces overall cost.

- Avoid using sealants as surface-applied fixes – When a sealant is applied this way, it is exposed, and when it’s not protected, its quality can be compromised. When it’s exposed this way, the quality of sealants can degrade due to exposure to dirt, ultra-violet rays and ozone.

- Do not tighten screws with sealants too tight – When a screw with a sealant is over-compressed, the sealant can thin out and will not last as long.

Learn more about S-5! in their directory or visit www.S-5.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In