UP TO THE MINUTE

Looking at the lifespan of a metal roof

By Colin Murnan, Sheffield Metals International.

Metal roofing is popular for its durability, but how long does it actually last? Here are nine factors that can impact the lifespan of a metal roof.

The Metal Construction Association reports that, in the best-case scenario, a metal roof can last for six decades or more. But what defines that scenario? There are many factors that can alter how long a metal roof lasts, from the specific materials used to the design of the entire system. At Sheffield Metals International (SMI) we know all about this. As the leading distributor of metal coils, sheets and accessories for the standing seam industry, we have seen a variety of materials installed on homes and building all over the United States. This means we have had a front-row seat to see what factors change how long a metal roof lasts and what you can do to help extend its lifespan.

1 - Roofing system

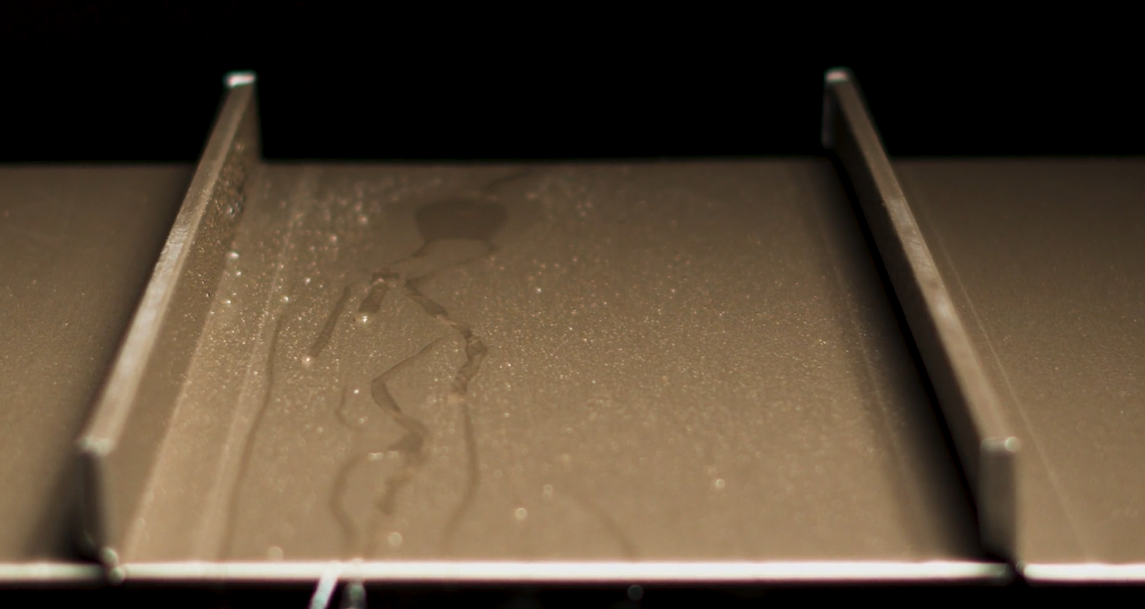

There are two main types of metal roofing systems — standing seam and exposed fastener. Standing seam metal roofs last longer because of a few key differences:

- Minimal exposed fasteners: Standing seam metal roofs mainly have concealed fasteners, which means fasteners will not be exposed to normal weathering effects such as moisture, wind and UV. This sleek design keeps the foundation of the system strong and increases its longevity. There are a few exposed fasteners in some trim details, but they are minimal.

- Weathertight warranties: Standing seam metal roofs come with very favorable warranties due to their solid designs. They’re a common choice for commercial projects due to the availability of weathertight warranties, which covers damage if the system leaks or fails.

- Engineered systems: Engineered panel profiles are systems designed and tested for high wind speeds, water penetration, air leakage, impact resistance and fire resistance. Standing seam metal roofing systems are becoming increasingly popular due to the availability of these engineered panel profiles and their favorability in areas prone to extreme weather such as hurricanes and severe storms.

While exposed fastener systems are still very durable, standing seam metal roofs are the top choice if you’re looking for the best longevity.

Check out this free comparison guide to the differences between standing seam and exposed fasteners!

2 - Materials

Another significant factor in determining how long your metal roof will last is which material will be used for the project. The two main materials used in metal roofing applications are Galvalume® and aluminum:

- Galvalume: A combination of steel, aluminum and zinc, Galvalume mixes various alloys to create a long-lasting, corrosion-resistant coating that is widely used in the metal roofing industry.

- Aluminum: Lightweight but very durable, aluminum is another quality choice for metal roofing projects. Aluminum is especially functional in coastal environments, as it oxidizes when it begins to corrode, preventing that common red rust you tend to see on steel.

Other more specialty metal roofing materials include zinc and copper, which are both extremely long-lasting but also come at a higher price point.

Remember that the best and longest-lasting metal roofing material will in part be determined by your unique location. If you’re located near the coast, you’ll likely want to look at getting aluminum, as this will help defend against corrosion and prolong both the functionality and aesthetics of your roof.

Download this cheat sheet on the different types of metal roofing materials!

3 - Metal thickness

Note that a metal roof’s longevity will also be based on its thickness. Standard thicknesses for metal roofing materials are 26, 24 and 22-gauge, with 26-gauge being the thinnest and 22 being the thickest of the three. The thicker the metal, the more rigidity it will have, making it a stronger, more durable material that can handle both weathering stress and impacts better.

24-gauge is the thickness where engineered systems become compatible, too, which means you can find a weather-tested, strong metal roof that will function well even in extreme weather environments.

24-gauge metal is very popular due to its balance between durability, workability (thicker metals are harder to work with during installation) and cost.

4 - Coating

Paint coatings will play a role in how a metal roof will stand up over time. The two main types of coatings for metal roofs are polyvinylidene fluoride (PVDF) and silicone-modified polyester (SMP). While SMP paint coatings are still solid choices, PVDF is the superior option and is commonly used on standing seam projects due to its robust durability, warranty coverage, impressive color retention and defense against chalking and fading. It also utilizes cool metal roofing properties, which can help reduce energy bills.

Paint coatings will play a role in how a metal roof will stand up over time. The two main types of coatings for metal roofs are polyvinylidene fluoride (PVDF) and silicone-modified polyester (SMP). While SMP paint coatings are still solid choices, PVDF is the superior option and is commonly used on standing seam projects due to its robust durability, warranty coverage, impressive color retention and defense against chalking and fading. It also utilizes cool metal roofing properties, which can help reduce energy bills.

Although slightly costlier, PVDF is a great choice because it will ensure the protection of your initial investment — the metal materials and the metal roofing system itself.

5 - Accessories

Not all accessories are created equal. Be sure to use the accessories recommended by the roofing manufacturer. Likewise, make sure that the lifespan of those accessories match that of the roof system you are installing. That way, your entire roofing system has a greater chance of staying intact for its full service life.

Accessories are as vital to the roofing assembly as the metal itself — make sure you’re choosing quality products that will last.

6 - Design

Design is critical in getting the most out of a metal roof. While the materials and system itself can be durable and long-lasting, it will only be as good as the comprehensive system it’s a part of. One common issue, for example, is dissimilar metal corrosion, which occurs when two types of metal that are chemically incompatible come into contact. This can occur even if the two metals aren’t touching. Rain runoff can travel from a copper tubing or accent to a steel roof, leading to the reaction.

Design is critical in getting the most out of a metal roof. While the materials and system itself can be durable and long-lasting, it will only be as good as the comprehensive system it’s a part of. One common issue, for example, is dissimilar metal corrosion, which occurs when two types of metal that are chemically incompatible come into contact. This can occur even if the two metals aren’t touching. Rain runoff can travel from a copper tubing or accent to a steel roof, leading to the reaction.

Taking time during the design phase and ensuring all the technical aspects are taken care of will ensure the roof will last as long as possible.

7 - Location

Metal roofs located in hurricane hotspots may have a lower average lifespan than others, as the extreme weather can cause a roof to take a beating. This is why it’s very important to take your unique region into account when planning for a metal roof. Certain panel profiles are better suited to certain regions, while specific materials, such as aluminum, are suited better for homes and buildings on the coast.

8 - Installation

Metal roofing, and particularly standing seam metal roofing, is one of the most challenging roofing systems to install, as it requires specific roofing details that need to be followed accurately and constant problem-solving to work around flashing areas.

If done correctly, the finished job can offer all the advantages of metal roofs — sleek aesthetics, unmatched functionality and great durability. It’s important to find a trusted contractor that knows what they’re doing and will complete a quality job.

After installation, also be sure you’re keeping up with regular maintenance. While metal roofs may not require as much attention as traditional options, it’s still a good idea to schedule regular inspections to make sure everything is still in good shape.

9 - Quality supplier

As metal roofing continues to grow in popularity, there’s a been a rise in low-cost, “budget” metal roofing suppliers, which often pop up in metal roofing hotspots such as Florida and Texas. While these suppliers often offer low costs, the materials they’re selling may not be reliable, and you likely won’t get the true benefits of a long-lasting metal roofing system.

Instead, be sure you find a metal roofing supplier — and contractors — with proof of work and solid references to back them up.

Are you a contractor that needs the right materials for your next metal roofing project?

A metal roof that lasts over an entire lifetime starts with finding the right materials. Sheffield Metals provides painted Galvalume and aluminum coils and sheets. But we provide more than just materials – if you’re looking to put a metal roof on your home or building, we can connect you with reliable contractors in our network who would be happy to give you a quote.

For commercial projects, Sheffield offers comprehensive services through our Commercial, Architectural and Technical (CAT) team. We can assist during the design phase, help you choose the right panel profile and inspect during installation phases for weathertight warranty adherence.

Original article and photo source: Sheffield Metals International

Learn more about Sheffield Metals International in their Coffee Shop DIrecotry or visit www.sheffieldmetals.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In