UP TO THE MINUTE

Common Problems with Rollforming Machines - Part 2

By New Tech Machinery.

What is panel curvature and how can it be fixed?

Part one of this four part article covered oil canning and the ways it can be caused and prevented. In part 2, we explain another common problem contractors have faced with rollforming machines, which is panel curvature.

Problem #2 - Panel Curvature

What is Panel Curvature?

Another common issue that can occur with a roof panel machine is panel curvature, which occurs when the panels are not coming out of the machine in a straight line. There are two main types of panel curvature that you could experience:

-

Uphill - If a panel is running uphill, the ends of the panel are coming up off the deck while the middle of the panel is touching the deck.

-

Downhill - If a panel is running downhill, the center of the panel is coming up off of the deck while the ends touch the deck.

Why Does Panel Curvature Happen?

The most common reasons why panel curvature occur are:

-

Different materials respond in different ways, which may mean an adjustment to the camber station is required before panels will run completely straight.

-

The run-out stands, if applicable, are not adjusted to the correct height that the panels are exiting the machine from.

How to Fix Panel Curvature

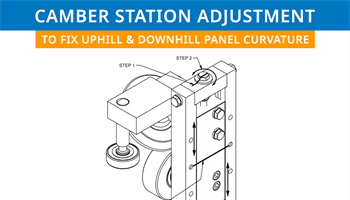

Every roller set is equipped with one or more camber stations toward the exit end of the machine. The camber station adjustment can be used to make the panel run straight if it is going uphill or downhill. Before you make any adjustments, make sure the run-out stands are properly adjusted for height and that the panel can run straight out of the machine.

If the run-out stands are in alignment, adjust the camber station as necessary using the following procedure:

-

Create a base point to start from by marking the top camber bolt as well as scribing a line across the center block and the two uprights.

-

If the panel is running downhill: Adjust the second to last station down by turning the top bolt counterclockwise.

-

If the panel is running uphill: Adjust the second to last station up by turning the top bolt clockwise.

(Note: The above instructions apply to a New Tech Machinery SSQ II™ MultiPro Roof Panel Machine. Additionally, it is recommended to make one small adjustment at a time, such as a ⅛ turn, and then run a panel to see the results after each change. Over adjusting the stations can create unpredictable and drastic results.)

Make sure to check back next week for part 3 covering shear misalignment.

Learn more about New Tech Machinery.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In